RToo 3D: Advanced Robotic X-ray Scanner for Art

Introduction

RToo 3D is an X-ray imaging system that combines single particle counting X-ray imaging detectors with the flexibility of collaborative robots. It provides customers with a powerful system tuned for non-destructive analysis of art. The major benefits of the system for art analysis are the hyperspectral X-ray imaging, superior image contrast and resolution combined with the viewing flexibility of robots.

Moreover, the system is modular, allowing easy extensions by other imaging modalities in the future.

Classical X-ray imaging systems measure just the intensity of X-rays passing through the inspected object. RToo also measures the wavelength of X-rays, allowing differentiation of materials (pigments) in the object, not only based on their overall X-ray attenuation, but also on their elemental composition.

In regular X-ray imaging systems, both the X-ray tube and the detector are fixed or move only in a limited range of directions (left, right, up, down). There is typically no flexibility to rotate about an arbitrary axis, i.e. look at the sample from different angles. Hence, it is not easy or even possible to inspect selected areas of larger structures, especially when they have complex shapes. Contrary to the classical X-ray imaging setups, the robotic system gives an almost complete flexibility of viewing angle. Therefore, robots allow “looking” with X-rays from a different perspective to give unprecedented information about the inspected object in 3D, without the need for a fully computed-tomography measurement.

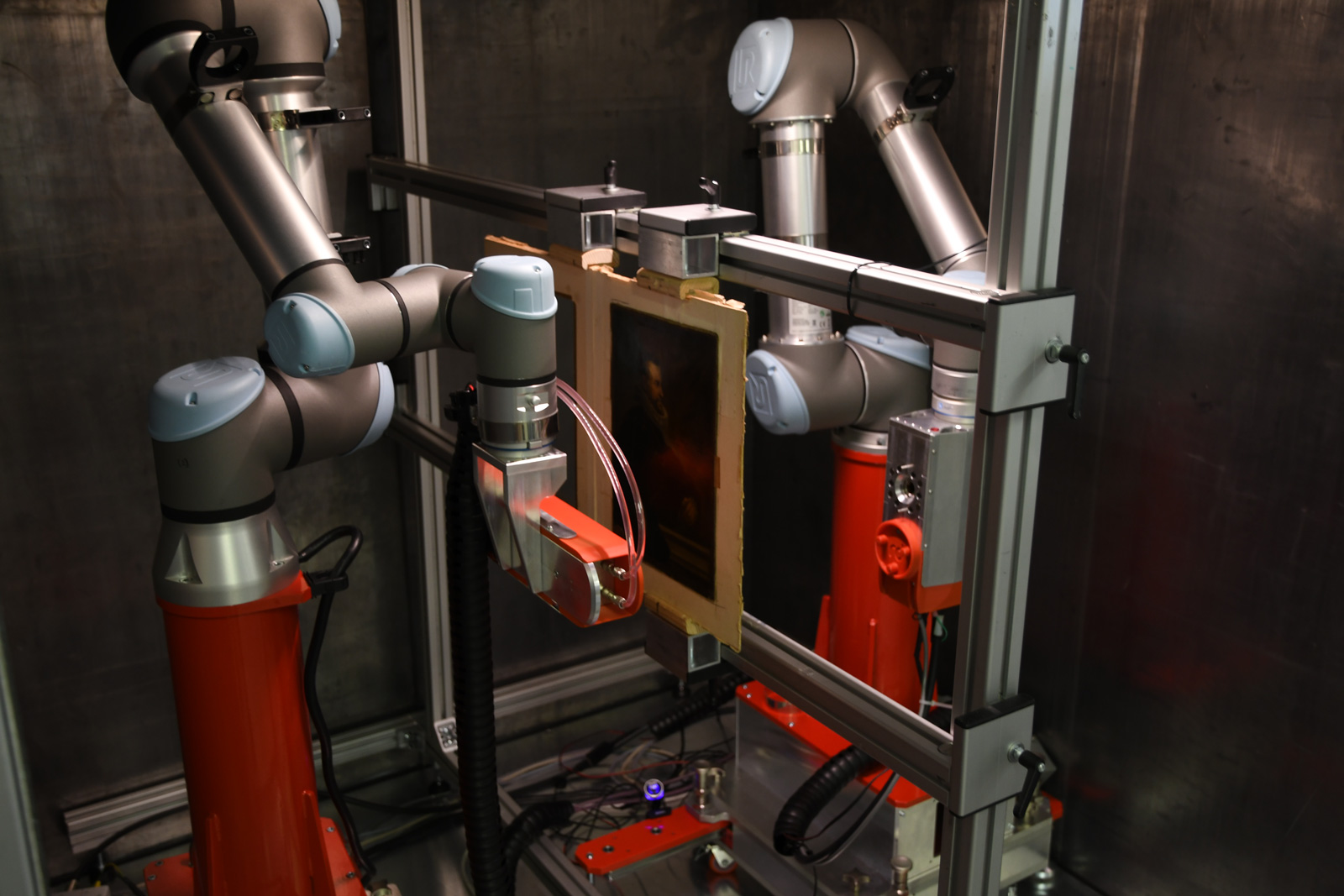

RToo 3D – X-ray robotic scanner

The left robotic arm holds a compact X- ray tube. The right robot carries a novel hyperspectral X-ray photon counting detector.

Spectral X-ray transmission imaging

RToo is capable of X-ray hyperspectral imaging where the whole X-ray spectrum passing through the sample is measured.

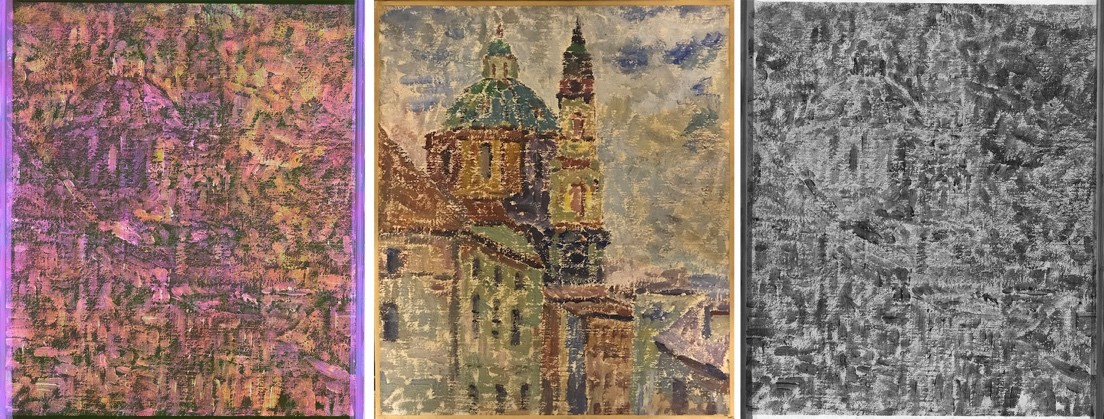

The spectral information can be used in heterogeneous samples where different materials need to be identified. The X-ray images can be “colourised”, emphasising different materials, or can be filtered to extract given materials only.

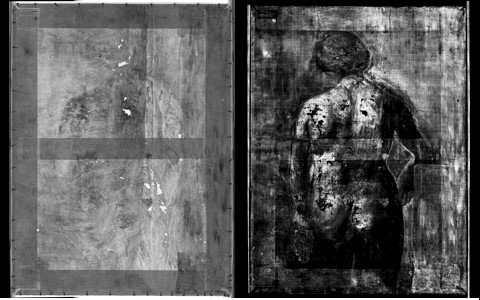

The capability of the hyperspectral scanning is well demonstrated on a painting from 19th century, where the signal of lead-containing pigment could be extracted to reveal an overpainted nude.

Samples can be scanned using the mode where both the X-ray tube and detector move together. The advantage of this scanning mode is that the X-ray tube / detector distance can be short, hence the X-ray intensity is higher and scanning faster.

Spectral “colour” X-ray image

The colours are associated with material differences identified in the painting.

X-ray scan and the spectral information

Left: X-ray scan of a painting.

Right: the spectral information was used to extract the lead containing pigment signal revealing overpainted layers of a hidden painting.

The scan was done in the mode where both the X-ray tube and detector move together.

The robotic X-ray scanner highlights

- The cutting edge photon counting X-ray imaging detector Widepix 1×5 MPX3 Si. It is an entirely new generation of X-ray imaging detectors based on Medpix3 chip with two energy discrimination thresholds per pixel.

- 2D spectral X-ray scans with parallel movement of X-ray tube and detector for thin samples.

- 2D spectral X-ray scans with X-ray tube stationary and moving detector suitable for thicker samples.

- Scans can be performed at an arbitrary scan plane orientation, with a scan area of up to 1.0×0.7 m2.

- Easy to setup scan by robot manual positioning using the “free run” mode.

- Realtime X-ray inspection using 3D mouse control of robots.

- Pair of collaborative robotic arms Universal Robots UR-5.

- X-ray tube Oxford Instruments Apogee (50kVp @ 1mA, 30 µm spot size, Be window).

- Mechanics for robot support.

- X-ray shielded cabinet 1.85×1.85×1.85 m (WxHxL) including interlocks and safety warning light. The cabinet is ready for radiation safety certification in UK.

- Control PC or Mac.

- Scanner control and data processing software.

Specifications

| Parameter | Value |

|---|---|

| Max Scan volume* | H: 1300 mm, L: 700 mm, W: 450 mm |

| Scanner footprint | 1850 mm x 1850 mm (Height: 1850 mm) |

| Scan rate in B&W mode | Approx. 350 mm2/s |

| Scan rate in full spectral mode |

Approx. 40 mm2/s |

| Inspection axes | 3D Translation (horizontal, vertical axis and magnification) 3D Rotation |

| Scan modes | 1. Area scan for thick samples (fixed X-ray tube position) 2. Area scan for thin flat samples (detector and X-ray tube move together) 3. Parallax free scan for samples with oriented structures 4. 6D real-time inspection. |

| Control software | RadalyX Studio |

| Data processing | Cloud based processing integrated to RadalyX Studio |

| Resolution | 55 µm |

| X-ray tube | 50kVp, 1mA |

| Radiation shielding** | Pb layer 2 mm thick |

| Radiation dose** | << 1 µSv at the box surface |

| Pixel detector | WidePix® 1×5 with Si sensor photon counting spectral detector |

| CCD camera for macrophotography** | Scanning range the same as for X-rays Spatial resolution of 50 µmMacro scans aligned with X-ray image for easy analysis |

| Power consumption | Approx. 660W |

* Larger objects are scanned in sections.

** Optional item.

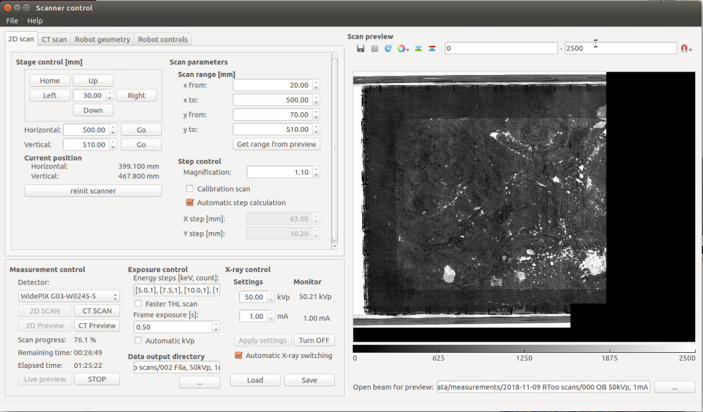

Software: RadalyX Studio

RToo is equipped with a control software, Radalyx Studio. Radalyx Studio allows the operator to perform on-site calibration for the whole scanner in a few steps. Then the user can easily set the scan range, the X-ray, and the detector parameters as well as perform different types of inspections as follows:

- Area scan for thick samples (fixed field of view).

- Area Scan for uniformly flat samples (multiple fields of view).

- 6D real-time inspection with complete control over the robots to translate horizontally, vertically, and magnify the image. Moreover, it allows 3D rotation to view the inspected part from an arbitrary angle (integrated with 6-axis Mouse).

Finally, RadalyX Studio processes and stitches the images into one final image. Also, the user can choose between different filters and manipulate the image dynamic range.

In case it is required to scan the same sample several times, the operator can save all the scan parameters and re-run the exact scan again.

The resulting scan images are exported to bitmap images for easy viewing or editing in common software, such as Adobe Photoshop.

Objects can be inspected in the “6D” realtime X-ray imaging mode. The robotic system is in this case controlled online using a 3D joystick. The mode is easily configurable in the RadalyX Studio.

X-Ray images

Left: X-ray image colorized based on material differences identified using the spectral information

Middle: photo of painting

Right: regular X-ray image

The immediate feedback between the operator’s action changing the viewing angle and the real time X-ray images makes it a perfect tool to learn 3D structure of the sample without the need to run a fully computed-tomography. Moreover, the real time imaging reveals structures at the full resolution of 55 µm. The scan can be recorded as a video for later reference.

Extensions under development

The flexibility of robots allows extension system capabilities by improved and extended data processing:

- Realtime X-ray inspection using virtual reality with stereoscopic view. This option will turn the robotic system into “X-ray goggles”, giving the operator a natural way to inspect objects with X-rays.

- Material analysis using artificial intelligence. The neural networks will bring a higher selectivity of materials (pigments) in the scan. It will also allow identification of individual pigments in the whole scanned area.

The updates and extensions are planned for the years 2020 and 2021. The scanner has a modular design. This means that other imaging modalities can be added as options. Modules under development are:

- XRF and XRD imaging probe.

- Infrared imaging measurement head.

- UV imaging measurement head.

- Raking light imaging.

- 3D surface scanning.

Resulting images of all imaging modalities will be aligned with a pixel precision to easily inspect relations between the data measured by each tool.

Interested to hear more about our technology?

Please contact Josef for personal presentation or visit one of our Demo Days in Prague.